Fastco Industries—located in Grand Rapids, Michigan—produces a wide variety of fasteners using the cold heading process as the basic forming method. They’re a proven supplier focused on superior quality and striving for zero defects with 100% on-time delivery.

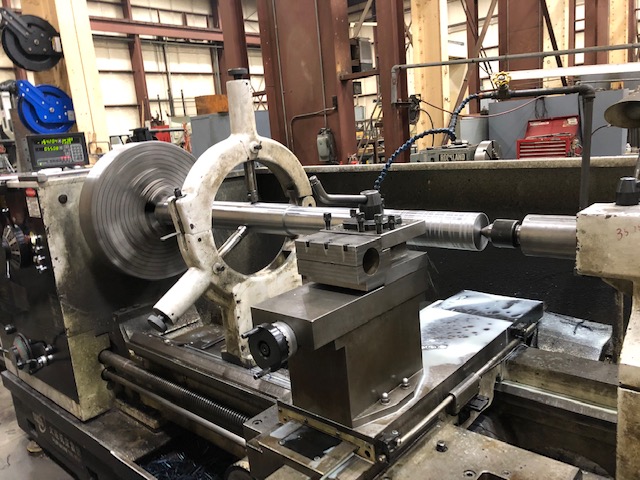

Recently, Fastco Industries reached out to us with a hot job: a crank shaft had busted into multiple pieces. Within one hour, we had picked up the materials from the customer and had it back into our emergency repair and machine shop.

It was so shattered that, once we brought it in house, we had to duct tape it back together to even understand what we were working with! We took photos, studied the measurements of the shaft, and looked at photos that Fastco had of when it was in working order.

“I was incredibly impressed with how they took a box of broken parts with no drawings and were able to piece together a new shaft that fit and worked the way we needed it to,” said Denny Lynn, of Fastco.

This particular shaft lies within the heart of one of their vital machines. So, without it, their operations came to a halt. For companies like Fastco, every minute of downtime is lost operation and productivity time.

The OEM quoted them six weeks for new parts—but we completed the entire project in just three. We ordered steel, fabricated new parts, and assembled them into the new shaft—all cheaper than if they had gone with the OEM’s quote!

“We’ve worked with HEL for years and will use them again. They always do a great job. And everytime we bring them an emergency, they step up to the plate and handle it with class—and with cost and operation time in mind,” Denny added.