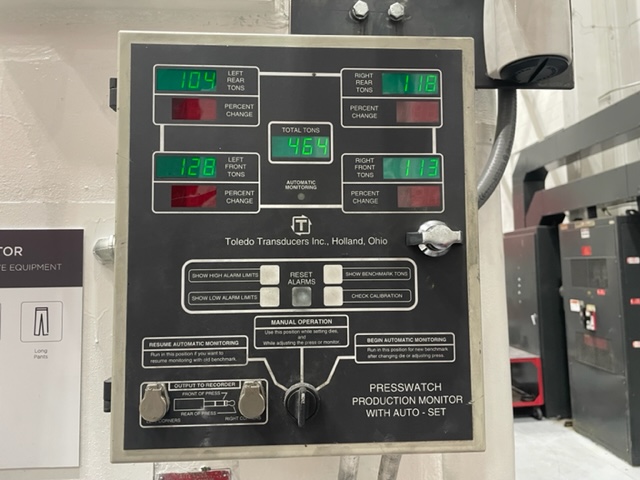

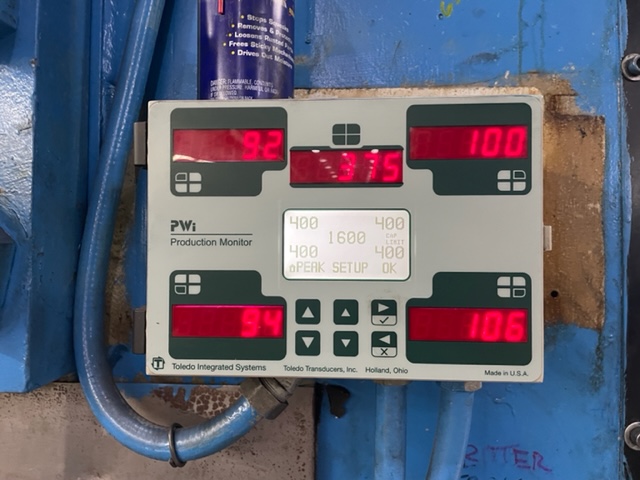

A tonnage monitor is a mounted sensor that reads the amount of tonnage produced by the press as it makes a part. They should be calibrated annually to avoid damaging the equipment—resulting in incredibly expensive maintenance bills.

HEL is the sole provider of tonnage monitor calibrations in West Michigan, and we would love to talk to you about scheduling this annual maintenance check.

Keep reading to learn why it’s so important to keep your tonnage monitor aligned.

Why is it so important to have my tonnage monitor calibrated annually?

Presses with tonnage monitors need to be calibrated at least once per year to provide accurate readings. Over time, vibration and overloading can cause the tonnage monitoring system to become inaccurate.

An improperly calibrated tonnage monitor is a concern, as it can lead to major damage of the internal components of the press or your tooling. In fact, we’d say it’s the second most important annual maintenance to do, after lube for your press.

What does a tonnage monitor calibration cost?

The cost for a tonnage monitor calibration varies on the size and number of presses we calibrate. Please call us for an exact quote.

Let us help you extend the life of your press. Give us a call today!